Scope 3 ESG Considerations

Scope 3 ESG considerations encompass indirect emissions associated with a company's value chain, including emissions produced during the production and transportation of materials. Local sourcing aligns with Scope 3 ESG principles in several ways:

Carbon Emissions Reduction: By choosing local suppliers, subcontractors can substantially reduce the carbon footprint of their construction projects, contributing to greenhouse gas reduction targets.

Resource Efficiency: Local suppliers often adopt more sustainable practices, such as recycling and reducing waste, supporting environmental responsibility goals.

Economic Growth: Supporting local businesses fulfills social responsibility by creating local jobs and enhancing community prosperity.

Transparent Governance: Collaborating with local suppliers fosters transparent and accountable governance, crucial for responsible business practices.

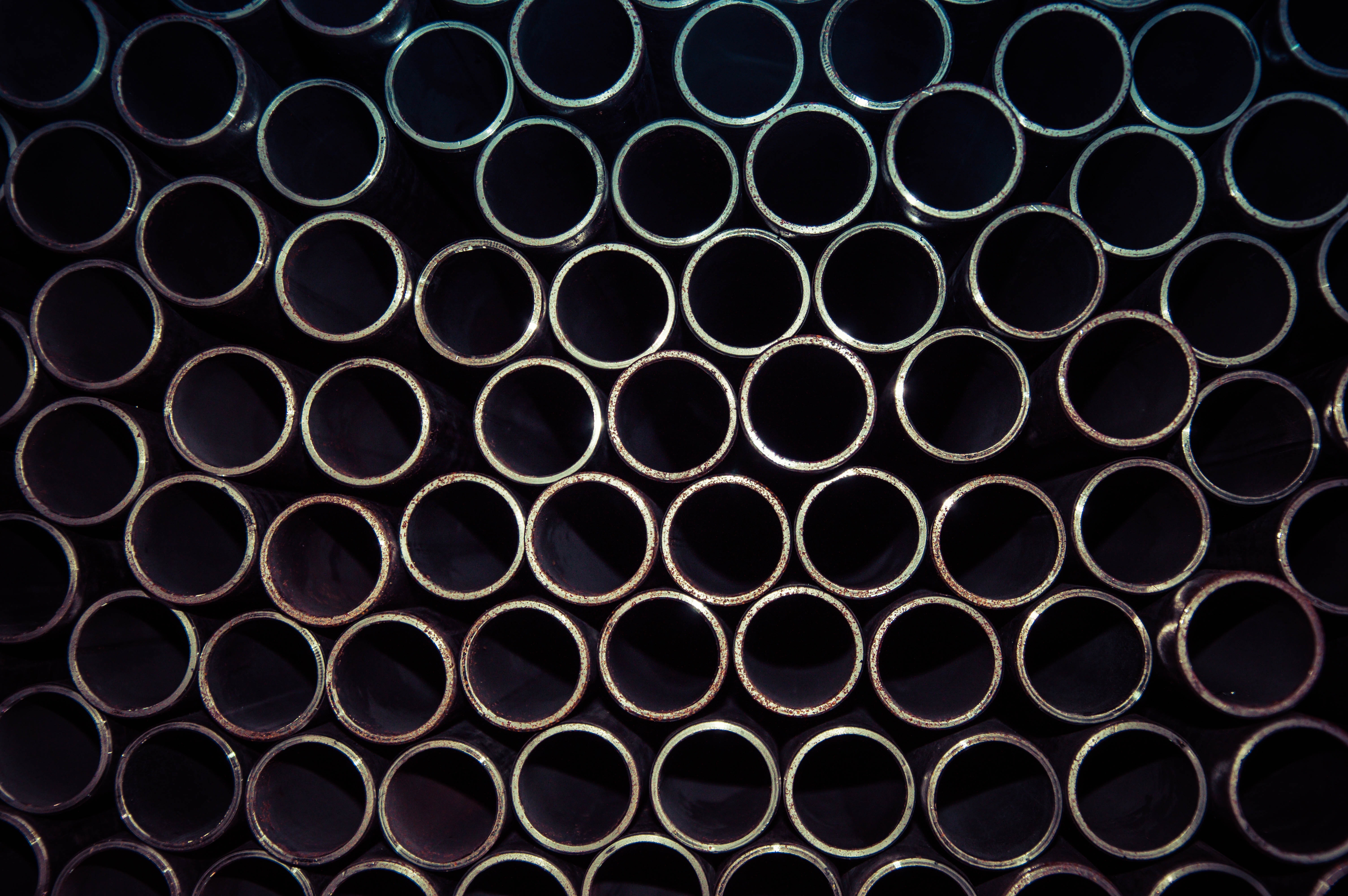

Finding Local Suppliers

To source steel locally, subcontractors can employ these strategies:

Research: Utilise online directories, industry associations, and recommendations from colleagues to identify local steel suppliers.

Site Visits: Inspect local supplier facilities to assess product quality, variety, and reliability.

Request Quotes: Obtain quotes and product information from multiple local suppliers to make informed decisions.

Establish Partnerships: Build long-term relationships with local suppliers to ensure a steady and dependable supply chain.

Steel is the backbone of construction, offering strength, resilience, and versatility. Subcontractors can harness the benefits of local sourcing to reduce their environmental impact, bolster local communities, and adhere to Scope 3 ESG principles. By cultivating strong relationships with local suppliers, subcontractors can enhance the quality and sustainability of their projects while contributing to a more resilient and responsible construction industry. In doing so, they become key players in advancing sustainable practices within the construction sector.