A robust local supply chain – encompassing not only materials, but also services and trades – plays a vital role in the success of construction projects across the UK. Local sourcing supports sustainability, boosts efficiency, and delivers significant social and economic value through increased local spend and employment opportunities.

By aligning procurement with framework and client project requirements, engaging local suppliers, subcontractors, and skilled tradespeople helps to drive community benefit while ensuring compliance and quality delivery.

In this piece, we explore how building with locally sourced materials, services, and trades lays the foundation for a more resilient, inclusive, and future-ready construction industry.

Reduced Carbon Emissions

Transporting materials long distances contributes to carbon emissions and the environmental impact a construction project has. By sourcing materials locally, contractors can minimise transportation-related emissions, reducing the carbon footprint of their projects and supporting sustainability goals.

Faster Delivery Times

A local materials supply chain plays a crucial role in the UK construction industry for several reasons. From sustainability to efficiency, local sourcing offers a wide variety of benefits that can make a significant difference in the success of construction projects.

Local suppliers can often offer faster delivery times compared to suppliers located further away. This enables construction projects to proceed more efficiently, minimising delays and ensuring timely completion.

Greater Flexibility and Responsiveness

Local suppliers are typically more accessible and responsive to the needs of construction contractors. They can quickly adjust to changes in project requirements, provide timely assistance, and offer customised solutions to address specific challenges.

Support the Local Economy

Sourcing materials locally contributes to the economic vitality of the surrounding community. It supports local businesses, creates jobs, and strengthens the local economy by keeping the revenue within the region.

Sourcing materials, services, and trades locally goes far beyond convenience — it actively contributes to the long-term economic vitality of the surrounding community. By working with local suppliers, subcontractors, and tradespeople, construction projects help retain revenue within the region, fostering economic circulation that benefits a wide range of local stakeholders.

This approach stimulates job creation across multiple levels of the supply chain — from manufacturers and merchants to trades and service providers — helping to reduce unemployment and develop local skills. It also empowers small and medium-sized enterprises (SMEs), enabling them to grow alongside larger contractors and participate in framework and client-led opportunities that might otherwise be out of reach.

Ultimately, prioritising local sourcing builds stronger, more self-sufficient communities, reinforcing social value targets and aligning with public and private sector goals around community benefit, net zero, and inclusive growth.

Enhanced Collaboration Opportunities

Building relationships with local suppliers fosters collaboration and partnership opportunities between construction contractors and suppliers. This collaboration can lead to innovation, knowledge sharing, and mutually beneficial outcomes for both parties.

Engaging local suppliers, service providers, and trades opens the door to stronger, more agile partnerships between construction contractors and the regional supply chain. These relationships go beyond transactional interactions — they foster a culture of collaboration, trust, and shared goals that can drive long-term value across a project’s lifecycle.

Proximity enables more frequent and meaningful communication, faster problem-solving, and greater responsiveness to changing site conditions or client requirements. Local partners often have a deeper understanding of regional regulations, planning challenges, and labour markets, offering insights that can improve project outcomes.

This close collaboration also promotes innovation — from co-developing sustainable solutions and improving buildability, to streamlining logistics and reducing waste. By working together, contractors and local suppliers can identify opportunities to reduce costs, improve timelines, and deliver better quality, all while aligning to framework guidelines and client expectations.

In the long run, these partnerships strengthen the local construction ecosystem, enhance supply chain resilience, and create a collaborative network that can be mobilised quickly and effectively for future projects.

Quality Assurance

Local suppliers are often known entities with established reputations in the community. Contractors can have greater confidence in the quality and reliability of materials sourced locally, reducing the risk of project delays or quality issues.

Compliance with Regulations

In some cases, local sourcing may be required to comply with regulations or specifications set by clients, government agencies, or industry standards. This includes requirements related to sustainability, environmental impact, or social responsibility.

Resilience to Disruptions

Relying on a local materials supply chain can enhance resilience to external disruptions, such as transportation disruptions, supply chain bottlenecks, or unforeseen events like natural disasters. Local suppliers may be better positioned to respond to and recover from such disruptions compared to suppliers located further away.

By prioritising local sourcing, contractors and housebuilders can contribute to sustainable, efficient, and resilient construction practices. A local supply chain can ease the burden of many current industry challenges like the environmental impact of construction and delays in sourcing materials. Businesses that embrace local sourcing are setting themselves up for success.

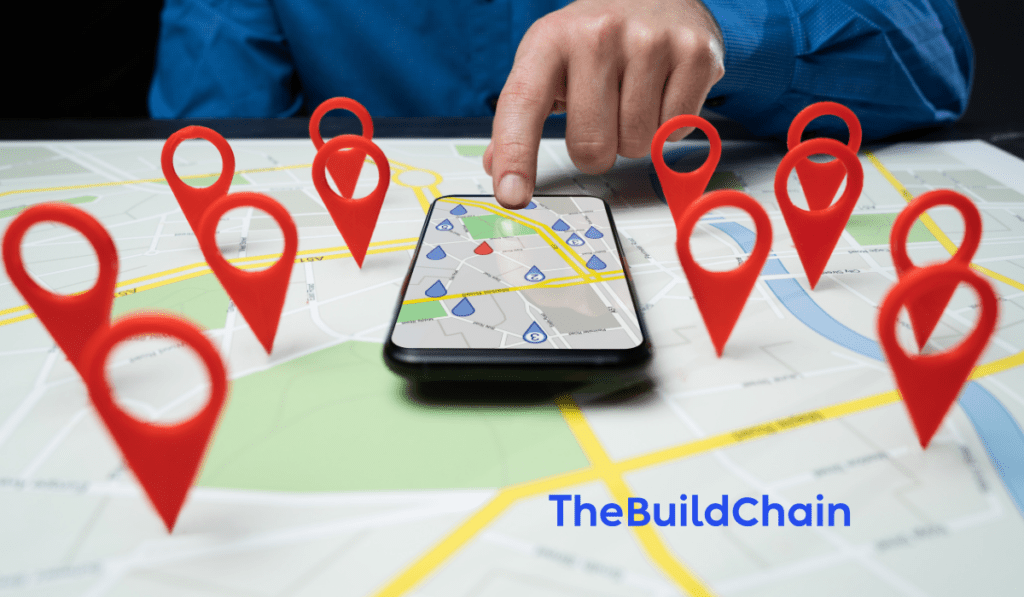

Adopt a local supply chain quickly & easily with The Build Chain

At The Build Chain, we recognise the challenges in adopting a local supply chain. If your work takes you all over the UK, it might be harder to establish relationships with local merchants and the process of finding suitable suppliers is often a manual, time consuming process.

That’s one of the problems we’re addressing with our online materials procurement platform, which transforms the process of buying materials.

Materials enquiries sent through The Build Chain are automatically matched to suppliers within a 30 mile radius of your site postcode, making it quick and easy to find new suppliers that are close to your site.

To find out more about how it works, book a demo – you can begin sending enquiries the same day!