In construction, every decision impacts your bottom line—from where you source materials to how quickly you secure the best price. Yet, many subcontractors still rely on outdated, manual procurement processes that don’t provide visibility into spending, supplier performance, or cost-saving opportunities.

The solution?

Data-driven procurement.

By leveraging real-time insights, supplier analytics, and cost tracking, subcontractors can cut costs, avoid delays, and stay ahead of the competition. Here’s how.

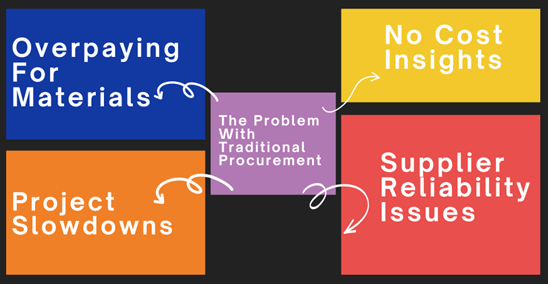

The Problem with Traditional Procurement

Most subcontractors still use phone calls, emails, and spreadsheets to manage procurement. This manual approach creates blind spots that can lead to:

❌ Overpaying for materials – Without visibility into price fluctuations, you could be missing better deals.

❌ Supplier reliability issues – No tracking of past performance leads to unexpected delays.

❌ Project slowdowns – Lack of procurement planning can result in last-minute scrambles and higher costs.

❌ No cost insights – Without data, it’s impossible to see where you’re overspending or how to optimize your process.

Simply put, guesswork doesn’t work anymore.

How Data-Driven Procurement Changes the Game

By using technology to track, analyse, and optimize procurement, subcontractors can turn insights into smarter decisions.

1️⃣ Real-Time Pricing = Smarter Spending

💡 Problem: Prices fluctuate, but without live data, subcontractors often lock in at the wrong time or overpay for materials.

✅ Solution: With a real-time procurement platform, you can compare prices instantly, securing the best deal when it matters.

2️⃣ Supplier Performance Tracking = Fewer Delays

💡 Problem: Relying on suppliers without knowing their track record can result in delayed deliveries and unreliable service.

✅ Solution: Data-driven platforms track supplier reliability—helping you choose vendors with proven performance.

3️⃣ Spend Analytics = Reduced Costs

💡 Problem: Without tracking procurement spend, it’s impossible to see where you’re losing money.

✅ Solution: Procurement data helps analyse spending trends, identify waste, and optimize purchasing decisions—leading to significant savings.

4️⃣ Proactive Procurement = No Last-Minute Scrambles

💡 Problem: Ordering materials at the last minute increases costs and causes project delays.

✅ Solution: Procurement platforms use predictive analytics to suggest when and where to source materials, keeping your projects on track.

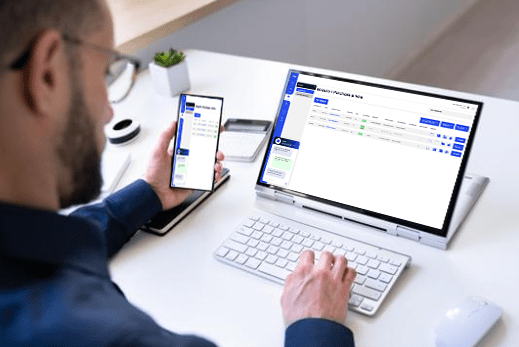

How The Build Chain is Powering Data-Driven Procurement 🚀

At The Build Chain, we know subcontractors don’t have time to waste. That’s why we built a platform that puts real-time procurement data at your fingertips.

✅ Instant supplier matching – Find the best materials without endless searching.

✅ Real-time pricing & quotes – Compare multiple prices in minutes, not days.

✅ Supplier performance insights – Work with vendors you can trust.

✅ Spend tracking & analytics – Get full visibility into procurement costs.

📉 The result? Lower costs, smarter spending, and faster projects.

Data-Driven Procurement is No Longer Optional – It’s Essential

Subcontractors who embrace digital procurement and data insights will stay ahead of rising costs, supplier disruptions, and industry competition. Those who don’t? They risk higher expenses, wasted time, and lost opportunities.

The question is: Are you making procurement decisions based on real data—or just guessing?