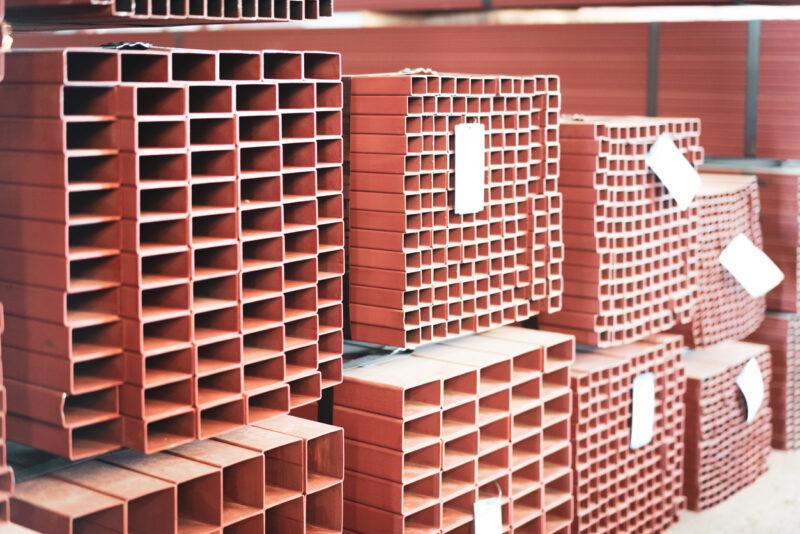

Streamlining the procurement process for construction materials is crucial for ensuring efficiency and cost-effectiveness in construction projects. Here’s our practical guide with essential tips and best practices.

Define Clear Requirements

Clearly outline the specifications and quantities of materials required for the project. Work closely with project managers, engineers, and architects to understand specific needs and any unique requirements.

Centralised Procurement Management

Establish a centralised procurement team or point of contact to oversee all material purchases. This helps in maintaining consistency, avoiding duplications, and leveraging bulk purchasing.

Vendor Evaluation and Selection

Thoroughly vet potential suppliers based on their reputation, track record, and ability to meet delivery schedules. Consider factors such as quality, reliability, and past performance.

Negotiate Favorable Terms

Negotiate pricing, discounts, and payment terms with suppliers to ensure cost-effectiveness. Explore long-term partnerships for better deals.

Utilise Technology

Implement procurement software for better tracking, analytics, and communication. Automate routine tasks like order processing and invoicing.

Streamlined Approval Process

Develop a clear and efficient process for approving purchase orders to avoid delays. Establish spending limits for different team members and ensure proper authorisation levels.

Real-Time Inventory Tracking

Implement a system to track inventory levels in real-time. This helps in preventing overstocking or stockouts, reducing storage costs.

Bulk Purchasing and Buying Groups

Consolidate orders and negotiate bulk discounts. Consider joining buying groups to benefit from collective purchasing power.

Quality Assurance and Compliance

Ensure that all procured materials meet required quality standards and comply with industry regulations. Regularly audit and monitor supplier performance.

Risk Management

Identify potential risks in the supply chain and have contingency plans in place. Diversify suppliers to reduce the impact of disruptions.

Continuous Improvement

Regularly review and update the procurement process based on performance metrics and feedback. Stay informed about new materials and technologies that may offer cost savings.

Collaboration and Communication

Foster open communication channels between the procurement team, project managers, and other stakeholders. Share information on lead times, order status, and any potential issues.

Environmental Sustainability

Consider environmentally friendly materials and suppliers. Evaluate the life cycle costs and benefits of materials to ensure long-term sustainability.

Training and Development

Invest in training for procurement staff to stay updated on industry trends and best practices. Foster a culture of continuous improvement within the procurement team.

By implementing these tips and best practices, procurement professionals can optimise their procurement processes, resulting in increased efficiency and cost-effectiveness. Regularly reassess and refine these strategies to adapt to changing project requirements and market conditions.

Efficient Construction Materials Procurement with The Build Chain

Using The Build Chain for construction materials procurement makes it simple to implement many of these tips.

With our platform, it’s easy to centralise procurement processes because it brings everything into one dashboard.

After submitting one enquiry form, you are instantly connected to local suppliers who send quotes for your consideration. Our inbuilt live chat functionality streamlines the negotiation process and makes it easy to build relationships with suppliers.

Continuous improvement is made possible by providing data driven reports on all procurement activity and the focus on local suppliers increases sustainability.

Want to give it a try?